Woodworking is the skill of making items from wood and includes cabinetry, furniture making, wood carving, joinery, carpentry, and woodturning. Regarding hobbies, having a supportive community around you can help your passion flourish. Having someone to turn to when you have questions and being able to show your achievements to those who care can be very motivating.

Reddit’s woodworking community is an example of such a supportive network. They are there for each other when they come across challenges and don’t spare praise when their fellow members show off impressive creations. With an incredible 4.9 million members and counting, this community celebrates professionals and roots for beginner hobbyists. Please scroll down to find a selection of the most recent projects the members shared online and our conversation with two of the members.

01. This Is A Cat-Themed Wooden Chess Set That I Designed And Sculpted Myself

One of the members of this community is Ryan Andrusky, a woodworker specializing in bespoke boxes and the stunning art of marquetry. His woodworking journey has been quite winded and full of passion for crafts. He began with origami, a hobby he picked up after tearing a ligament in his thumb when he was 19. His love for these intricate paper creations grew so much that he started making his own paper, eventually leading him down the rabbit hole of bookbinding. After an unsuccessful venture into a bookbinding business, he took a break from handiwork but returned to it in 2018 when he was diagnosed with Rheumatoid Arthritis. That’s when he dived into woodworking and never looked back.

In 2020, during the pandemic, he stumbled upon French marquetry, the art of applying veneer pieces to form decorative patterns. He instantly became obsessed with learning the craft, acquired the necessary tools, and started practicing. Three years later, he attended the first-ever Wonders of Wood: Inlay and Marquetry conference as a student scholarship winner.

02. My Complicated-Looking Greenhouse Without Cutting Any Compound Angles

03. Curved Shelf Experiment

These days, he makes billiard and game tables for a small local business (check it out here) that he feels fortunate to be a part of. In his free time, he continues to master the art of marquetry, which is his hobby and passion. “What drew me into marquetry is the complexity of it. I am often drawn to more difficult, almost magical crafts. <…> The challenge and the feeling of completing a project drives me to the next one, always thinking about improving or creating something more outstanding.”

The most recent creation he is proud of is the “Bee on a ‘honeycomb'” comb, which sounds like a fascinating project that involved using horn material. “I used a technique I have never seen in marquetry before to create the bee’s transparent-looking wings. I used a steer horn for the wings. When hot pressed and thinned down, they become very transparent. I first created the background with the bee’s body inlaid into my comb body. Then I inlaid the wings halfway through that layer so that the background and body of the bee would still show through, creating a persuasive trompe l’oeil effect.”

04. My Third Project Through My High School Class What Do You Think?

05. DIY Woodpecker Clock Made By Myself. The Material Is 3mm Plywood

06. Bee On A “Honeycomb”

When asked to elaborate on marquetry, Andrusky shines with enthusiasm. He explains three different ways of cutting wood for this craft. There’s stack cutting, also known as Boulle marquetry, double bevel or conical cutting, and piece-by-piece cutting. You can cut marquetry with a small knife that’s good for thinner commercial veneers or with a larger knife called a shoulder knife that can cut through thicker pieces. You can inlay marquetry directly into solid surfaces with chisel router tools or even laser technology. But the technological advancements don’t entice him: “I am not interested in that kind of work at all; I do this because I want to do the cutting and have all the fun!”

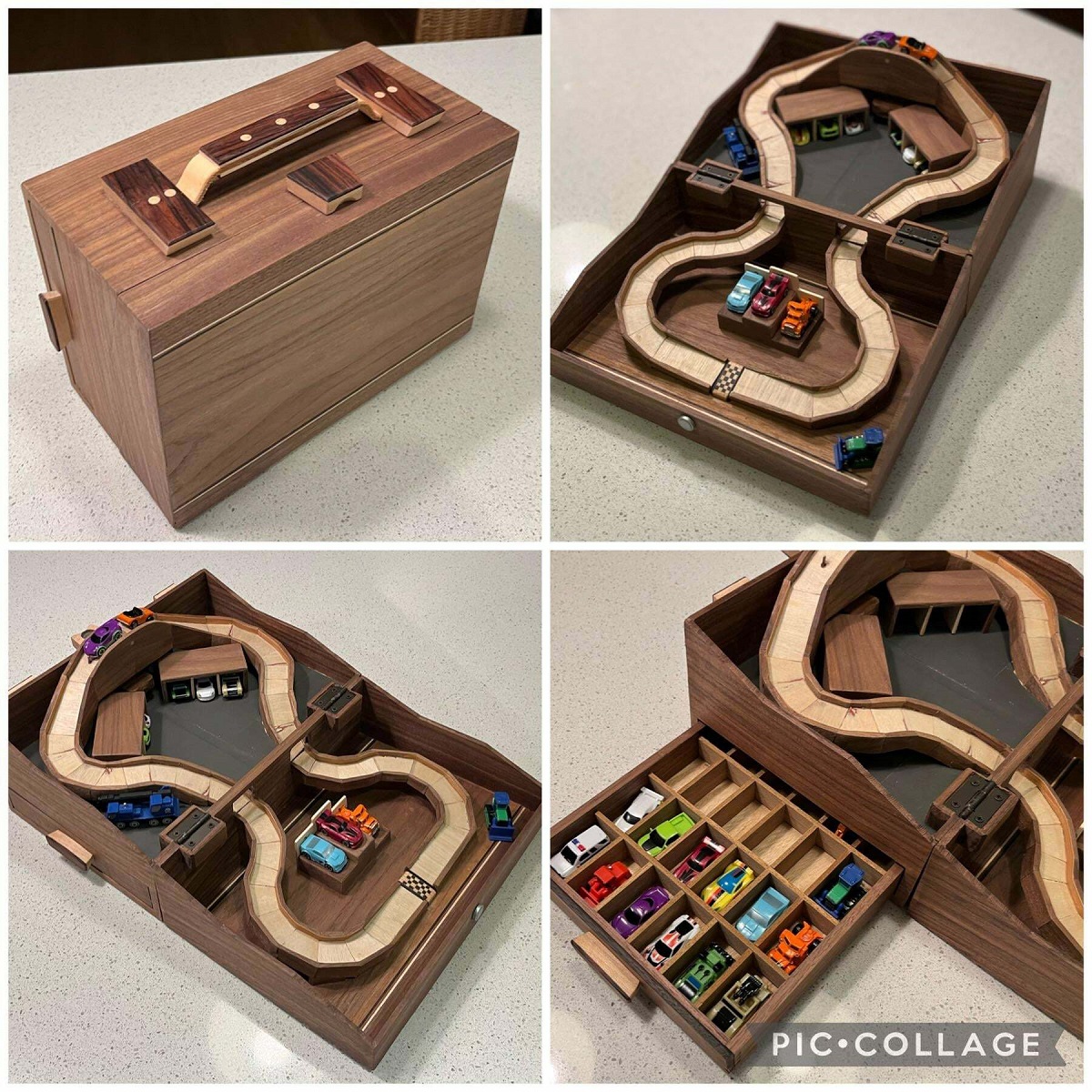

07. I Found Out They Were Making Micro-Machines Again And Made A Birthday Present For My Youngest

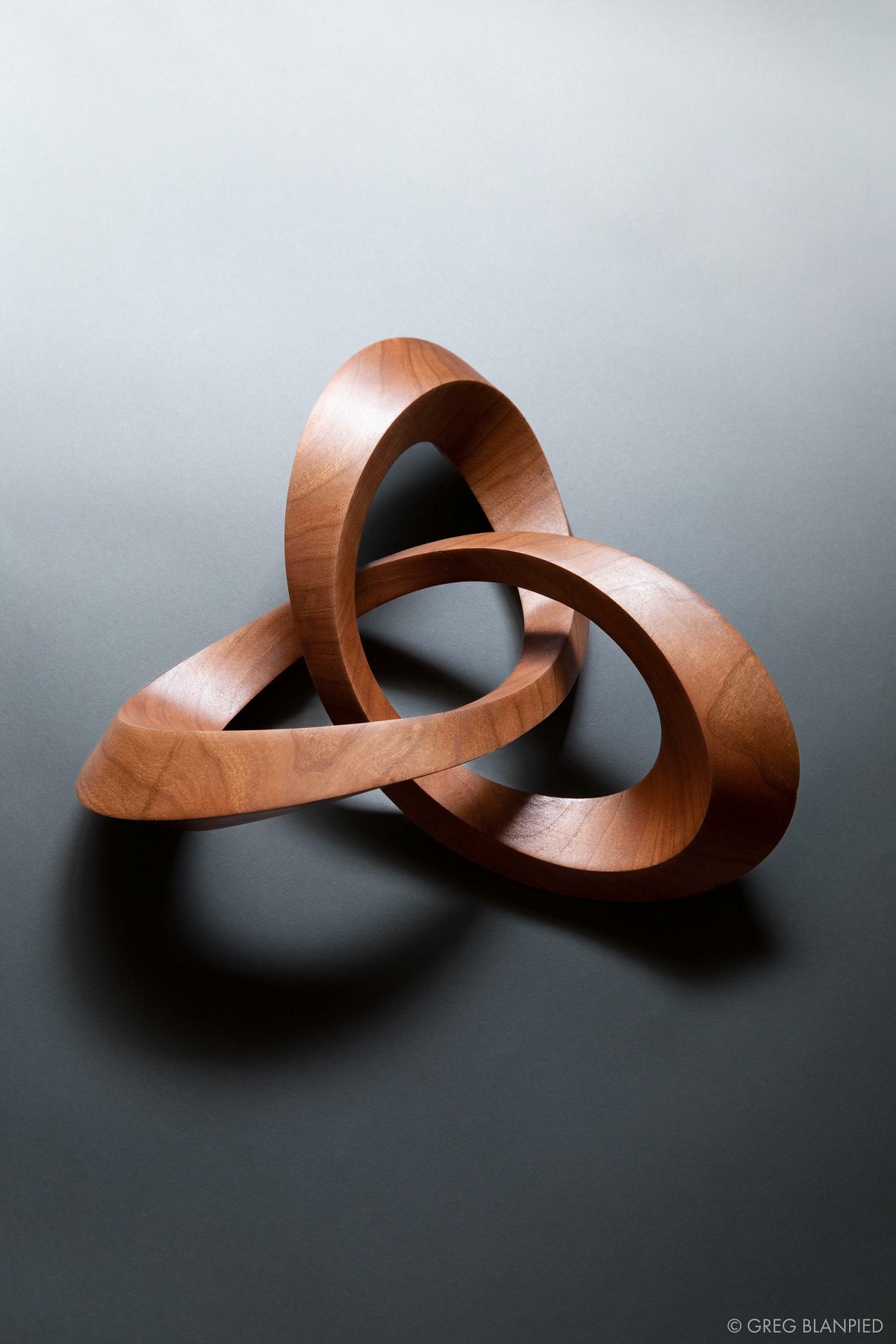

08. I Made A Trefoil Knot Out Of Cherry!

09. I Made A Spice Rack

His process of creating a marquetry piece is quite remarkable and very involved. He starts with a design or tracing of the piece and preparing his veneers and other materials he’s using to inlay (metal, stone, bone, horn, etc.). He then cuts the pieces out in whatever method is best suited. When done, the pieces are typically shaded with hot sand (acids or even simple charcoal crayons can also be used for that). After that, he glues it down to a substrate, sands, scrapes, and finishes. He always sticks to traditional methods and uses protein glues (hide glues, fish glue, etc.) and finishes. “I make my pieces last hundreds of years and still be reversed and fixed if necessary.”

10. Officially, My Cutest Project Ever!

11. Hi Everybody, Here Is My Second Attempt To Create A Sculpture With Wood. My Father Taught Me

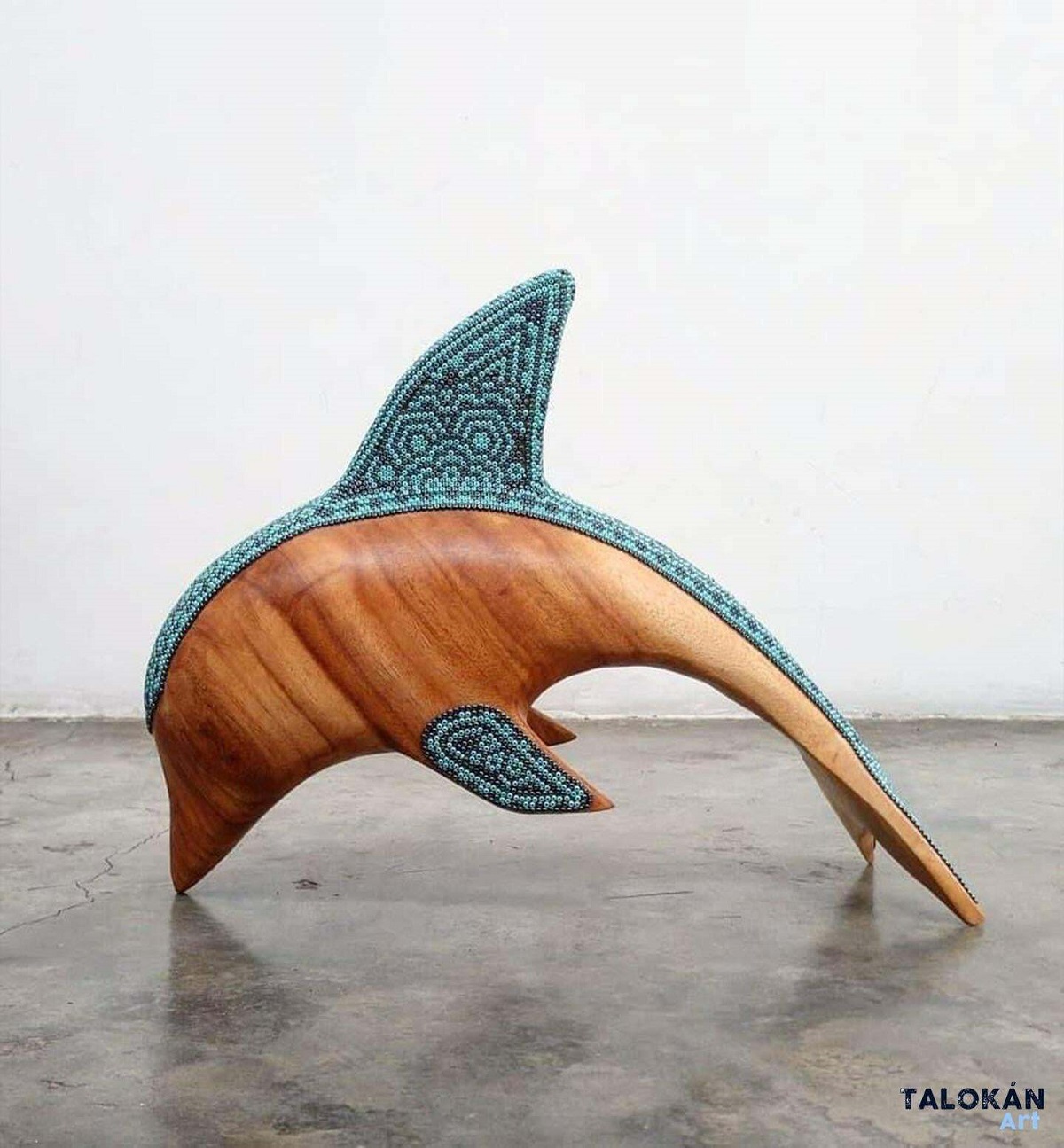

12. Wood Dolphin: I Made And Decorated It In A Pattern Inspired By My Huichol Culture

These intricate processes yield impressive work and make Andrusky very happy. “I love the challenge and the process of marquetry. It is not easy, and succeeding gives me ample dopamine! This craft has also helped me lower my stress levels and see life differently. It has improved my Rheumatoid Arthritis to the point that I no longer take medications for it. Dealing with stress is vital in our daily living, and marquetry provided that for me.”

13. My Wife Said She Could Never Tell If I Was On A Call In Our Home Office

14. Walnut Mountain Shelf Made From My Carver

15. Took A Little Too Much Pride In Our Work This Week

Woodworker Hunter Locke had a way more straightforward path to his craft. His love for woodworking started when he married and moved to his first unfurnished apartment. “As [my wife and I] scoured the internet for nice furniture, I realized that we probably didn’t have the budget. I’ve always been good with my hands, so I started to research building furniture and realized that it sounded delightful to me.” Now, at 25, he’s already five years into his woodworking journey and has his own custom furniture business (check it out here).

At this point in his career, he’s primarily working on practical items. “I enjoy building ‘stand-alone furniture’ pieces like dining tables, chairs, etc.” With the help of traditional woodworking methods, he designs pieces meant to last for generations. However, Locke is also intrigued by more decorative pieces. “I have a couple of light fixture designs in my head.”

16. Kiwi!

17. Layered Plywood Spiral Staircase (With White Oak Treads)

18. Husband Bought 32 Old Windows And Is Using Them To Build Us A Greenhouse. It still Needs A Roof, But it Looks So Cool

Regarding his favorite pieces he’s made so far, a recent creation he loves is a bar cabinet shaped like a robot that he made as a wedding gift for his cousin. “She had sent me a reference image over a year ago that I had saved with the intention of building as their wedding gift. The time came, and I was able to build my take on the piece. It’s very different from what I normally build, but it was a fun challenge! And I think it turned out pretty great.”

19. My Screen Porch I Built In 2020

20. Fire, In Basswood

21. Made A Wall Ruler To Track My Grandchildren’s Growth

Nothing complicated, but I’m already getting requests to make more. So far, only one can stand up, so I’m way ahead of schedule. Simple but fun, it gives me joy!

Locke is also excited about all the learning possibilities that woodworking offers. “I am intrigued and excited to get into more bent lamination.” Making bent lamination involves cutting a board lengthwise into thin strips so they can bend easily. Then, you glue and clamp them back in order and place them in a particular bending form that allows them to bend into a specific shape. Once the glue cures, you have yourself a bent board. “I’m using this for dining chair seat backs, but I want to start using it in more places.”

22. My First Woodworking Project

23. A Small Gang Of Strange Birds In My Workshop. Quite Noisy And Keep Demanding Fish

24. My First Chair Took Me 10 Months To Finish (Elm)

Looking into the future, Locke has big plans ahead. He hopes to continue growing his signature collection and sell more and more of his pieces. “Eventually, I want to run a small-scale production shop that works solely on my designs, and I can still take on an occasional custom piece.”

25. My Wood Sculpture ‘Hildr’. Made From Walnut Timber And Limewood

26. I Carved This Giant Monarch Butterfly From Maple Wood!

27. Here’s An End-Grain Cutting Board I Made. It’s My First Try At This Design. There Were A Few Issues, But The Next Batch Will Be Better. Wenge, African Mahogany And Hard Maple

Finding a craft you can put all your love into is magical and life-changing. Having a community around to support that love only makes it more precious. The Redditors who found their place in the woodworking community can attest to that. If you wish to see more of their impressive works, check out the posts here and here.

28. Big Marquetry Project I Finished Today

29. When You Want To Carry A 17′ Kayak Inside A 6′ Wide Teardrop Camper

30. My Marshall Amp Dresser – Woodworking

31. Bought An Entire Walnut Tree And Built A Custom Wine Room With It

32. Dragon Priest Staves From Skyrim I Crafted Out Of Wood. They Are 140cm Tall

33. Funcle Status Archived; Bulldozer Bed Complete

34. This Was My Winter Project

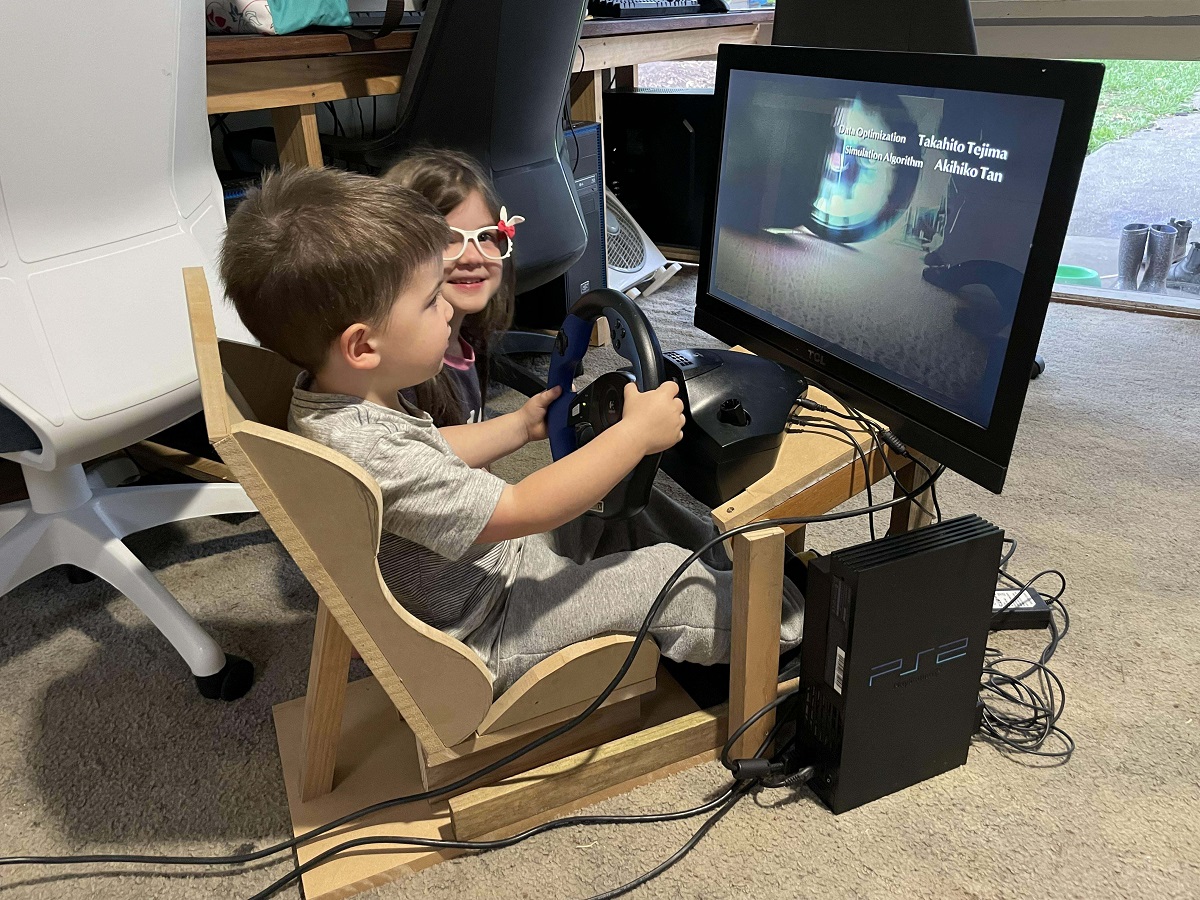

35. I Made A Little Person Very Happy Today

36. I Made A Tissue Box From Some Scraps Of Walnut And Cherry

37. Finished My First Piece Of Furniture Ever! Solid Cherry And Finished With Danish Oil

38. Tiger Wood Outdoor Shower

39. Made This From A Tree That Was In My Front Yard

40. I Made 60 River Coasters For My Upcoming Wedding

41. It Was Only My Second Cabinet Ever, And It Had To Be A Massive 28 Foot Wall Unit For The Shop I Work At

42. Olive And Pit Bowl, Oak

43. Walnut Side Table With Epoxy. LED Light Strip Underneath For Lighting Effect

44. Danish Cord Stool (First Time Weaving)

45. Set Of Media Cabinets I Made – A Mix Of Solid And Veneered Walnut

46. It’s Not Perfect, But $35 For All The Materials Beats Buying A New Door. Damn Dog Won’t Keep Me From Getting That Security Deposit Back

47. Bespoke Oak Pool Table – Woodworking

48. Rate My Skills For My First Project

49. I Built A French Cleat Digital Sandpaper Sorter That Keeps All Of My Orbital & Mouse Sanding Pads Organized

I didn’t want to have written labels, so I used cheap decade counters to denote the grit of each shelf of sanding pads. Now, I punch in grit value whenever I resupply pad types!

50. I Made A Millennium Falcon Bed For My Daughter

Like what you’re reading? Subscribe to our top stories.

Discussion about this post